Navigating Manufacturing Risks: How Contract Manufacturers Can Mitigate Tariffs and Supply Chain Disruptions

Disclaimer: The information provided in this blog is intended for general informational purposes only and reflects the status of tariffs and supply chain conditions at the time of publication. Given the dynamic nature of global trade policy, readers are encouraged to consult official government resources for the most up-to-date information. Spartronics will continue to update this content as needed to reflect major changes.

The Growing Complexity in Global Manufacturing

The global manufacturing landscape is evolving rapidly, driven by tariff fluctuations, geopolitical uncertainties, and supply chain disruptions. Contract manufacturers (CMs) are under increasing pressure to optimize production costs, maintain supply chain resilience, and ensure high-quality output while navigating these complexities.

For original equipment manufacturers in high-reliability industries such as aerospace, defense, and medical device production, disruptions can result in significant delays, cost overruns, and lost market opportunities. Traditional supply chain models that rely heavily on single-source suppliers or geographically concentrated production hubs—such as China or Mexico—are proving to be high-risk strategies.

To mitigate these risks, manufacturers are increasingly turning to specialty contract manufacturing partners that offer strategic geographic diversification, engineering support, and vertically integrated solutions. Leveraging multi-regional production facilities and robust supply chain networks provide clients with flexibility and risk mitigation strategies.

Spartronics stands out as a specialized contract manufacturer offering tailored service solutions for high-reliability industries, combining engineering expertise, strategic global locations, and end-to-end manufacturing capabilities.

The Role of Tariffs in Global Manufacturing

Tariffs have become a major factor in manufacturing cost structures, influencing decisions on sourcing, production locations, and supply chain design.

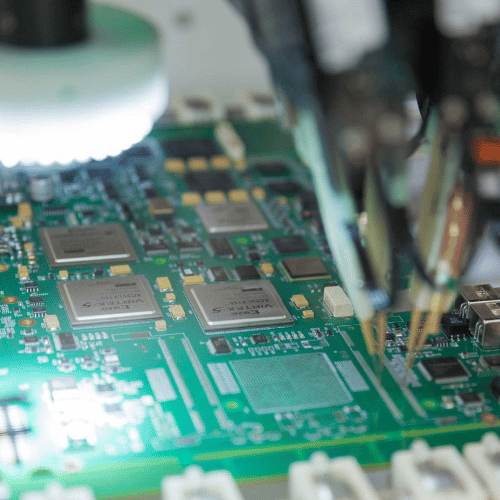

For example, the U.S.-China trade war led to a surge in tariffs on printed circuit board assemblies (PCBAs), semiconductors, and industrial components, significantly increasing costs for manufacturers reliant on Chinese suppliers. Recent tariff policies on goods from Canada and Mexico have made nearshoring strategies more complex, requiring companies to find alternative production hubs that offer cost efficiency without sacrificing supply chain agility.

Spartronics employs a strategic approach, with a state-of-the-art manufacturing facility in Vietnam, helping customers mitigate tariff risks while ensuring seamless production and delivery.

Vietnam, a Strategic Manufacturing Hub

As companies seek cost-effective manufacturing solutions outside of China, Vietnam has emerged as a premier alternative due to its favorable trade agreements, lower labor costs, and rapidly improving infrastructure.

Key Advantages of Manufacturing in Vietnam

Tariff Optimization & Free Trade Agreements:

Vietnam benefits from major free trade agreements (FTAs) such as:

• The Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP)

• The EU-Vietnam Free Trade Agreement (EVFTA)

• The ASEAN Free Trade Area (AFTA)

These agreements significantly reduce or eliminate tariffs on goods exported to the U.S., EU, Japan, and Canada, making Vietnam an ideal production hub for global manufacturers.

Lower Cost Structure

Compared to China, Vietnam offers competitive labor rates while maintaining strong manufacturing expertise, particularly in electronics assembly, high-reliability PCBAs, and precision machining.

Growing Electronics & Industrial Manufacturing Sector

Vietnam has invested heavily in advanced manufacturing capabilities, attracting global contract manufacturers and OEMs (Original Equipment Manufacturers) seeking cost-effective, high-quality production alternatives.

Supply Chain Diversification & Risk Reduction

For companies seeking alternative sourcing locations to reduce dependence on China, or other high-risk tariff countries, manufacturing in Vietnam provides a geopolitically stable and cost-effective solution.

Why Spartronics? A Service Solutions Partner for High-Reliability Manufacturing

Spartronics offers a comprehensive suite of services that goes beyond traditional PCBA assembly, including:

• New Product Introduction (NPI) & Prototyping

• Advanced Engineering Support & DFM (Design for Manufacturability)

• Supply Chain & Materials Management

• Precision High-Level Assembly & System Integration

• Testing, Quality Assurance & Regulatory Compliance

In addition to these value-added engineering services, Spartronics Vietnam holds a variety of industry standards and certifications. Most notable being, FAD Compliant, cGMP/QSR Registered and NADCAP.

By integrating engineering services, supply chain optimization, and advanced manufacturing capabilities, Spartronics functions as a true service solutions partner, helping customers reduce time-to-market and manage production complexity.

Spartronics’ Vietnam-Based Manufacturing with Dedicated Customer Support

With over 20 years of manufacturing in Vietnam, Spartronics’ state-of the art- facility provides customers with all the benefits of a low-cost, tariff-friendly production environment. While ensuring full transparency, quality control, and seamless project execution. Unlike other large CMs that prioritize high-volume production, Spartronics takes a customer-centric approach, offering personalized support and dedicated project management.

The Future of Resilient Manufacturing

For companies seeking a strategic, low-risk, cost-effective manufacturing solution, Spartronics’ Vietnam facility provides a compelling alternative—ensuring cost optimization, production flexibility, and long-term competitive advantage.

Ready to future-proof your manufacturing strategy?

Contact Spartronics today to learn how we can help you navigate global manufacturing risks and drive long-term success.

Contact Us